For every 10 people that leave the manufacturing sector as machine operators, only one person comes in, according to Rapid Robotics CEO Jordan Kretchmer.

This situation results in a massive labour gap that plagues the industry amid increased demand for locally manufactured products.

Furthermore, traditional robotics can be prohibitively expensive and extremely slow to set up for a production line. This is the issue Rapid Robotics, in collaboration with Markforged, seeks to address by offering easy and affordable automated processes with robotic arms and customised grippers at a fraction of the cost and time needed.

Faster throughput

Unlike enterprise businesses, small to medium manufacturing businesses struggle to weather the costs and time it takes to build automated processes.

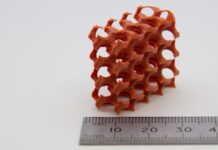

After its inception, Rapid Robotics ventured into a partnership with Markforged to develop the capability to print reliable and affordable grippers, reduce overall weight, and iterate quickly to ensure they provide customers with a customised solution that will withstand the stress of a heavy-duty manufacturing process.

“In traditional design, through CNCing and other operations where you have to outsource design, outsource parts, it’d take months. It was a task that was impossible with traditional systems integration, which is where Markforged comes in,” said Taylor Parker, a mechanical engineer at Rapid Robotics.

At times, Rapid Robotics is able to provide customers with a work cell after only two weeks from the first conversation. The robot is customised to suit the exact need the customer has straight from the start and can work 24/7 with no interruptions.

No two deployments are the same

“End-of-arm tooling and part manipulation is one of the most complex parts of programming a robot,” said Kretchmer.

Grippers can be bought off the shelf but they are extremely expensive and come with a weeks-long lead time. Furthermore, they come with inherent issues as these parts are not designed for the specific task needed.

“No two deployments are the same, every robot is fully customized. Every part is completely different. We need Markforged in order to get our robots to fit any solution possible,” according to Parker.

According to Kretmcher, with the flexibility and reliability brought by Markforged 3D printers, they will be able to successfully help reshore more manufacturing back to the US.