The race is on to make space components more dependable, affordable, scalable, and producible using agile manufacturing techniques as the aerospace industry moves quickly towards additive manufacturing (AM) as a method to convert innovative, physics-based designs into higher-performing parts.

To date, numerous industries have seen a dramatic transformation as a result of the developing field of 3D printing. This technology is not only in demand in the aircraft industry – it is a necessity.

Thus, two undergraduate students from Colorado University (CU) Boulder Aerospace Engineering Sciences program have worked with industry experts to develop a cost-effective and reliable rocket turbopump concept.

According to the case study, the main objective was to create a rocket component that could be produced in a single process. Not only would this reduce material and weight, but it would also significantly speed up production. Additionally, the avoidance of possible sources of mistakes that might happen with conventional joining procedures is another benefit of this strategy.

Curiosity fosters innovation

In January 2021, while still in his junior year of undergraduate study, Zach Lesan, the team’s first leader, had the idea for the project. In the fall of 2022, after Lesan had graduated and started an internship at SpaceX, his colleague Patrick Watson joined and took up most of the duties.

Lesan decided to dig in after finding scant to no proof that such a project was being conducted formally at the undergraduate level. He was confident that he could work on anything in addition to his studies because he was currently enrolled in one graduate-level propulsion course.

“I attacked the problem head-on,” said Lesan. “It was a huge opportunity to learn component design, complex assembly design, CAD, 3D-printing design principles, and a variety of software modelling solutions to first principles problems.”

Collaboration with companies as a catalyst

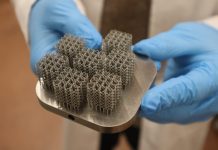

Early on, the duo approached companies such as Velo3D, a metal printing solutions supplier, and asked for their knowledge and resources. Through these collaborations, the two students received access to cutting-edge technology and were able to test their concept.

That online inquiry led to a chat with Zach Murphree, Velo3D’s VP of Global Sales and Business Development, and Gene Miller, Director of Technical Sales. Both supported Lesan and provided the project’s technology and services.

Lesan met his future co-designer Patrick Watson at the CU Sounding Rocket Laboratory (CUSRL) while developing the turbopump.

Setting goals and taking action

These days, single-part rocket designs and unified production strategies are being pursued by both independent engineers and commercial enterprises. The objective is to rely less on traditional joining methods like brazing, casting, and machining, which hinder functional performance, reduce reliability, and draw from a shortening supply chain. These goals are shared by Lesan and Watson, as well.

“A lot of companies cast their parts,” said Watson. “The real big breakthrough in turbomachinery for space or energy is 3D metal printing, Laser Powder Bed Fusion (LBPF), mostly. We can now print the performance geometries we want, iterate the designs, get the surfaces we need, and use machining more selectively. Metal 3D printing makes our project possible,” he said.

Watson also emphasised that what was not given or discounted has been paid for using their salary. He revealed they paid tens of thousands of dollars to remove support structures or manufacture conventional pieces.

The academic goals of the Reaper engine, which was inspired by a fiery pepper from South Carolina, were to investigate quick and more affordable methods of rocket production.

Lowering costs and improving dependability through additive manufacturing

Lesan had the fundamentals in place for the design work he was to conduct at CU Boulder, thanks to his early research in solid-state rockets as a teenager and data on turbopumps in hand since the 1960s. He needed to design his own MethaLOX model, one that used sophisticated metal AM. Lesan did not anticipate increasing their performance, but he and Watson hoped that with AM, they might save costs and improve reliability over previous systems.

“We have gotten rid of so many potential traditional failure modes by minimizing part count,” said Lesan. “The issue then with AM is porosity and part verification. We can look at our Velo3D build reports and see there were no errors in the process impacting quality.”

Meanwhile, Watson stated, “There are some parts we had to buy or conventionally manufacture.”

“The purchased parts are fittings, bearings, seals and fasteners to join flange sections. Otherwise, the focus was on creating a work-friendly, lower-cost system, that avoids traditional fit problems through combined parts,” he added.

Partnering with industry leaders

John Farnsworth, a professor at CU Boulder, together with Cameron Micksch and Paul Wingrove from the school’s machining lab assisted Lesan and Watson.

The private sector intervened with software, services, supplies, and guidance. The core team of two employed Velo3D for their metal printing, CFturbo provided essential design software and continuous support, while Silicon Valley Elite Manufacturing and EMP provided machining services.

Additionally, they acquired instruments from Kulite and Omega as well as seals from Gallagher Fluid Seals. Individual engineers at both the SpaceX and Launcher firms where they were interning, as well as Ursa Major and Andrew Mitchell, a former employee of Masten Space Systems who is now at Astrobotic, offered informal advice.

After finishing his internship with SpaceX, Lesan enlists in the military as a second lieutenant in the Space Force. Watson is completing his undergraduate degree and has a position with Launcher Space (a Vast firm) waiting for him.