Boral announced it would examine the viability of establishing a carbon capture facility in the Southern Highlands after receiving a $30 million Commonwealth grant to use Calix’s breakthrough carbon technology.

Boral and Calix will use the funding to investigate the potential of a commercial-scale plant that absorbs and compresses up to 100ktpa of CO2 emissions caused by the decomposition of limestone in the cement making process.

Boral Chief Operating Officer, Darren Schulz said Boral is committed to investing in projects that “create high performing products while reducing our carbon footprint”.

“This is game changing technology for our industry and will play a critical role in supporting customers’ sustainability targets,” Mr Schulz added.

“Together, Boral and Calix have access to the required infrastructure, technology and operational expertise required to deliver this project and lead the way in reducing emissions across the industry.

“By modernising Australia’s cement industry, we are enabling the growth of lower carbon construction materials, which are essential to jobs and local economies.

“I want to thank the Government for their support and understanding the need to transform the management of emissions in cement manufacturing.”

“If successful, we believe this project will enable the national rollout of carbon capture technology to Australia’s cement and lime industry creating smarter and more sustainable solutions for our customers.”

Cement manufacturing is a high-emissions business, accounting for roughly 7% of worldwide carbon emissions.

One of the most difficult tasks is minimizing the amount of carbon trapped in limestone and then released throughout the manufacturing process.

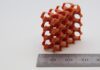

Calix’s technology re-engineers the existing process flows of a traditional calciner, indirectly heating the limestone via a special steel vessel. The unique process enables CO2 to be captured as it is released from the limestone.

To reduce financial risk, the project will be divided into three sections. The first phase of the project, which is planned to be finished in June 2023, is a thorough commercial model and pilot design that will examine the project’s engineering and commercial viability.

If the project is successful, Boral will consider investing more money in the technical and engineering design phase.

Calix Managing Director and CEO Phil Hodgson noted that while the company has been working hard to pilot its technology in Europe, this project represents a significant increase in carbon abatement ambition in Australia in a relatively short timeframe.

“It is great to be working with an Australian company such as Boral, with an Australian, home-grown technology, in a world-leading project,” Mr Hodgson concluded.