Australia’s Commonwealth Scientific and Industrial Research Organisation (CSIRO) has opened a 3D printing innovation centre in Clayton, Victoria.

Image credit: CSIRO

The $6 million CSIRO Lab 22 is set to boost Australia’s manufacturing sector as it will offer 3D printing technologies to Australian businesses.

“Manufacturing remains a key driver in our economy, but as the industrial landscape changes, the sector needs to transition to more innovative and economically viable technology,” said Minister for Industry, Innovation and Science, Christopher Pyne at the official opening ceremony.

“Emerging technologies such as metal 3D printing offer huge productivity gains and have the potential to turn Australia’s manufacturing industry on its head. The centre will enable manufacturers to innovate with less capital investment risk – one of the major barriers in adopting 3D metal printing.”

A total of nine Australian businesses have been taken on as CSIRO industry partners since May, including Made for Me and Keech3D.

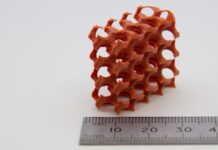

At the hub, businesses will have access to the latest 3D printing technologies and 3D printers that use titanium, aluminium, sand and so on.

Lab 22’s additive manufacturing equipment includes: Arcam A1, Concept Laser M2, Optomec LENS MR-7, Voxelject VX1000 and Cold Spray Plasma Giken. Cold spray deposition technology, laser heat treatment, surface engineering and advanced machinery are also available to improve efficiencies, performance and profitability.

CSIRO has a great track record of creating innovative 3D printed products with a number of industry partners, such as the mouthguard for treating sleep apnoea that the organisation developed in collaboration with dental company Oventus.

Other 3D printed products include customised lugs, developed with bike manufacturer Flying Machine, and titanium heel bone and rib implants developed with biomedical device manufacturer Anatomics.