Australia’s Innovative Manufacturing Cooperative Research Centre (IMCRC), the University of South Australia (UniSA) and BAE Systems Australia’s subsidiary, ASC Shipbuilding, are investing more than $4million in research to develop world-leading manufacturing technologies for BAE’s Hunter Class Frigate Program.

Spearheaded by UniSA, the local partnership will fund the development of digital manufacturing (Industry 4.0), improve shipyard planning and add unique data analytics and problem-solving capacity to the Hunter program.

IMCRC CEO Managing Director David Chuter said the partnership will ensure the Hunter class frigates are built using some of the most sophisticated innovations in manufacturing, while at the same time developing extraordinary capabilities and ongoing capacity for Australian shipbuilding and manufacturing.

“This partnership will provide enduring and uniquely Australian sovereign industrial capability and advance and mobilise local manufacturers, particular small and medium enterprises (SMEs), to support Australia’s naval shipbuilding strategy for generations to come,” Mr. Chuter said.

ASC Shipbuilding has been awarded a contract by the Australian Government to build nine Hunter class frigates for the Royal Australian Navy (RAN) in 2018. The Hunter program is the largest surface ship project in Australia’s defence history, and will create and sustain more than 5,000 jobs across BAE Systems and the wider Australian defence supply chain over the life of the program. This includes 1,000 apprentice and graduate roles.

Earlier this month BAE welcomed its first batch of shipbuilding apprentices that have been recruited from 10 South Australian schools. The apprenticeship program will allow the students to undergo the training while still completing their studies.

ASC Shipbuilding Continuous Naval Shipbuilding Strategy Director Sharon Wilson welcomed the partnership with UniSA and the opportunity to work with expertise of local researchers to drive innovation in digital manufacturing and come up with innovative solutions to production challenges.

“Together we’re creating a first-of-its-kind digital environment through the entire ship design and construction to improve productivity, quality and safety outcomes in the shipyard, and underpin growth and longevity in the naval shipbuilding industry in Australia.”

“These innovations will be significant across the local supply chain so that Australian manufacturers can start their digital journey, building their capability to be involved in the Hunter program and future shipbuilding projects,” Ms. Wilson said.

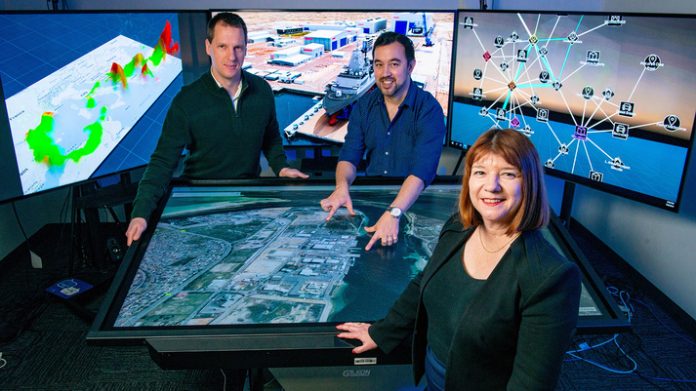

Meanwhile UniSA chief collaborator Professor Bruce Thomas explained how narrative visualisation and big data processing can deliver, reshape and refine the highly complex manufacturing environment across the timeframe required for each frigate build.

“Through data fusion, machine learning and artificial intelligence data analytics, and visualisation technologies, we will be bringing intelligent planning systems and smart ‘human in the loop’ decision making to the project.”

“What we learn by adapting, trialling and testing to suit the Hunter class frigate’s design – will support the prototyping later this year, but will also build significant knowledge for wider application in Australian manufacturing,” Professor Thomas said.

Read the full report from BAE Systems Australia here.

Image credit: BAE Systems