A team of researchers, headed by RMIT University, has created and manufactured a surface with virus-killing capabilities, offering the potential for mitigating disease transmission in hospitals, labs, and similar high-risk settings.

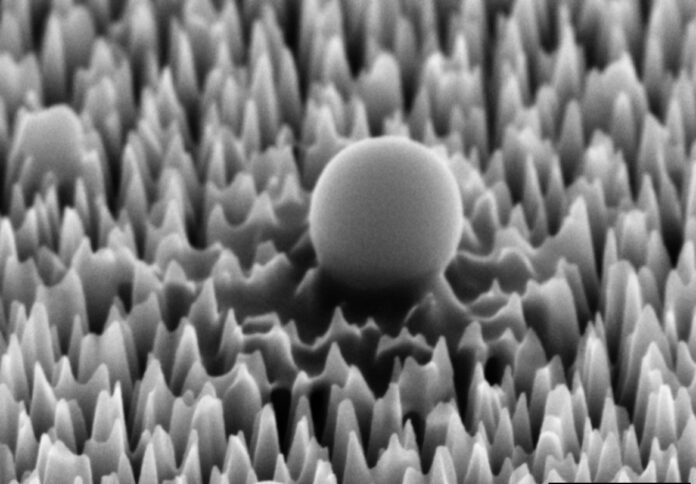

Crafted from silicon and adorned with minuscule nanospikes, the surface demonstrates remarkable efficacy in neutralizing viruses upon contact, the university stated in a news release.

Laboratory experiments involving the hPIV-3 virus, responsible for ailments like bronchitis and pneumonia, revealed that 96 per cent of the viruses were either torn apart or rendered incapable of replication, thereby preventing infection.

Dr Natalie Borg, the corresponding author from RMIT’s School of Health and Biomedical Sciences, highlighted the sophisticated nature of this virus-killing surface, which appears as a flat black mirror but harbours tiny spikes engineered specifically to combat viruses.

“This material can be incorporated into commonly touched devices and surfaces to prevent viral spread and reduce the use of disinfectants,” Dr Borg stressed.

Manufactured at the Melbourne Centre for Nanofabrication, the nano-spiked surfaces start as smooth silicon wafers, subjected to ion bombardment to strategically remove material.

The end result is a surface bristling with needles, each a mere 2 nanometers thick and 290 nanometers high – substantially smaller than human hair strands.

The research team, spearheaded by RMIT Distinguished Professor Elena Ivanova, draws upon years of expertise in studying mechanical methods inspired by nature to combat pathogenic microorganisms.

The design of the nano-spiked surface was refined through theoretical analysis and practical experiments, culminating in its remarkable effectiveness at damaging virus structures and piercing membranes.

Samson Mah, the study’s first author, emphasised the practical implications of this research, particularly in high-risk environments where exposure to hazardous biological materials is a concern.

Mah, who progressed from an RMIT-CSIRO Masters by Research Scholarship to pursue his PhD with the team, said he envisions the implementation of this technology as a critical step towards enhancing containment measures against infectious diseases.

This interdisciplinary collaboration, spanning two years and involving researchers from RMIT, Universitat Rovira i Virgili (Spain), CSIRO, Swinburne University, Monash University, and the Kaiteki Institute (Japan), underscores the global effort to advance virus containment strategies.

Funded by the ARC Research Hub for Australian Steel Manufacturing and the ARC Industrial Transformational Training Centre in Surface Engineering for Advanced Materials, this groundbreaking study, titled “Piercing of the Human Parainfluenza Virus by Nanostructured Surfaces,” is published in ACS Nano.