Story by CSIRO

Australian Minister for Industry and Science Ian Macfarlane today congratulated CSIRO on its role in an international collaboration that has led to a world-first in surgery, using a 3D printed titanium sternum and rib implant that was designed and manufactured in Melbourne.

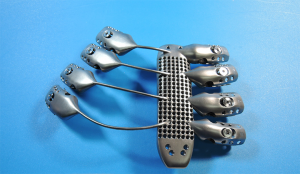

Image credit: CSIRO

Mr Macfarlane said the technology that allowed a Spanish cancer patient to receive the titanium sternum and rib implant was designed and developed in Australia, in a collaboration between a Melbourne-based medical device company, Anatomics, and CSIRO’s 3D printing facility, Lab 22, at Clayton.

“This breakthrough is an impressive example of what can be achieved when industry and science come together,” Minister Macfarlane said.

“This collaboration crossed disciplines and international boundaries, with a clear benefit for both this individual patient and for surgical practice.”

After being diagnosed with a chest wall sarcoma, the 54-year-old man’s surgical team made the decision to remove his sternum and a portion of his rib cage and replace it with an implant.

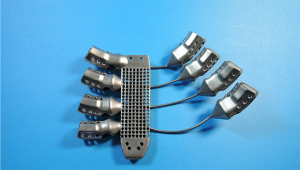

Image credit: CSIRO

The implant was designed and manufactured by medical device company, Anatomics, who utilised the CSIRO’s 3D printing facility, Lab 22.

The surgical team, Dr José Aranda, Dr Marcelo Jimene and Dr Gonzalo Varela from Salamanca University Hospital, knew the surgery would be difficult due to the complicated geometries involved in the chest cavity.

“We thought, maybe we could create a new type of implant that we could fully customise to replicate the intricate structures of the sternum and ribs,” Dr Aranda said.

“We wanted to provide a safer option for our patient, and improve their recovery post-surgery.”

That’s when the surgeons turned to Anatomics.

After assessing the complexity of the requirements, Anatomics CEO Andrew Batty said the solution lay in metallic 3D printing.

“We wanted to 3D print the implant from titanium because of its complex geometry and design,” Mr Batty said.

“While titanium implants have previously been used in chest surgery, designs have not considered the issues surrounding long term fixation.

“Flat and plate implants rely on screws for rigid fixation that may come loose over time. This can increase the risk of complications and the possibility of reoperation.”

Through high resolution CT data, the Anatomics team was able to create a 3D reconstruction of the chest wall and tumour, allowing the surgeons to plan and accurately define resection margins.

“From this, we were able to design an implant with a rigid sternal core and semi-flexible titanium rods to act as prosthetic ribs attached to the sternum,” Mr Batty said.

Working with experts at CSIRO’s 3D printing facility Lab 22, the team then manufactured the implant out of surgical grade titanium alloy.

“We built the implant using our $1.3 million Arcam printer,” Alex Kingsbury from CSIRO’s manufacturing team said.

“The printer works by directing an electron beam at a bed of titanium powder in order to melt it. This process is then repeated, building the product up layer-by-layer until you have a complete implant.

“3D printing has significant advantages over traditional manufacturing methods, particularly for biomedical applications.

“As well as being customisable, it also allows for rapid prototyping – which can make a big difference if a patient is waiting for surgery.”

Once the prosthesis was complete it was couriered to Spain and implanted into the patient.

“The operation was very successful,” Dr Aranda said.

“Thanks to 3D printing technology and a unique resection template, we were able to create a body part that was fully customised and fitted like a glove.”

Minister Macfarlane said this type of collaboration can transform the way industries operate and compete in international markets.

“Collaboration is the key to boosting Australia’s innovation performance. Initiatives like our Industry Growth Centres will foster these links and relationships which are critical to future successes like this,” Mr Macfarlane said.