Digitisation and sustainability drive manufacturing

Australian manufacturing is thriving despite cost pressures, supply chain issues and labour shortages. A new CommBank report shows how digitisation and sustainable practices are reshaping the sector.

The Australian manufacturing sector is approaching a new growth phase

While there is no doubt the current health pandemic has had an impact on many Australian manufacturers, the inaugural CommBank Manufacturing Insights report suggests the sector is on the precipice of a new growth phase.

5 Effective Ways to Protect Your Payroll Data

Australian institutions regularly face cybersecurity threats, and these risks are getting bigger and more threatening as years pass by.

Habitat for Humanity 3D Prints Concrete Home Using Autodesk Fusion 360

Habitat for Humanity and PERI 3D Construction discuss the process of building the organization’s first 3D printed home, including how Autodesk Fusion 360 played an important role.

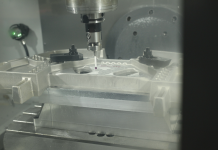

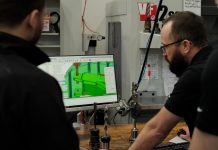

How Conturo Prototyping are delivering complex prototypes faster with the Fusion 360 Machining Extension

Machining complex parts can be challenging, expensive and time consuming – but Conturo Prototyping is changing that with the advanced 5-axis CNC machining capabilities provided by the Autodesk Fusion 360 Machining Extension.

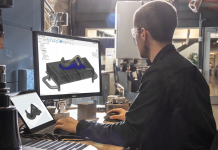

Instantly Advance Your Manufacturing Capabilities with Fusion 360 Extensions

If you have used Fusion 360, you’re already aware that it’s a very powerful tool. A single cloud program for design, modelling, and manufacturing, Fusion 360 gives you

How mid-market manufacturers can seize advantage

A new study from Forrester Consulting is a warning for mid-market operators struggling to update their tech systems, but it also shines a way forward.

Autodesk Fusion 360 and Formlabs Team up

Autodesk and Formlabs are teaming up! You may not have noticed just yet, but Autodesk Fusion 360 has an expansive additive manufacturing workspace designed to help prototyping, researchers, additive engineers, designers and everyone else get the most control over their 3D printers.

Nesting & Fabrication with Autodesk Fusion 360

If you’re cutting a large number of parts out of flat sheet stock with varying dimensions and prices, nesting is a crucial piece of the workflow to help eliminate guesswork and minimise waste.

The Growing Influence of 3D Printing in the Military

Additive manufacturing solves the many issues that the Military has within their unpredictable and complicated supply chain.