Article by Christopher Hunt, Additive Manufacturing Manager, Accumold

Some 30 years ago now, additive manufacturing (AM) — which back in the day was more typically known as rapid prototyping, — disrupted (as the name suggests) the prototyping stage of product development. The ability to print parts in 3 dimensions from CAD solid models facilitated concurrent engineering, as within days of a design being complete, all relevant product development departments could sit together analysing an accurate prototype, and designs could be easily re-iterated to overcome potential downstream manufacturing issues.

For a tooling manager to be able to initiate changes in product designs to streamline the tooling process a few days into the development of a product knocked weeks if not months off product development cycles.

Move on 25 years, and AM began disrupting the traditional manufacturing paradigm once again, this time in the area of production. In general terms, AM technologies have become increasingly sophisticated over time, and the precision and accuracy of builds in a variety of materials means that AM is now challenging legacy manufacturing processes in terms of speed, cost, and tolerance attainment.

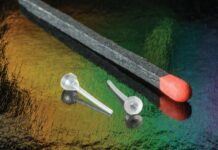

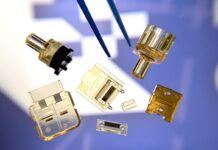

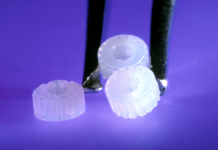

This history of AM over the last 30 years, however, is only really accurate when looking at the production of macro-sized parts and components. It is only in the last few years that AM has been able to disrupt the area of micro manufacturing, as it is only in the last few years that innovators have managed to refine the AM process to achieve the micron level tolerances and surface features that have been the preserve of legacy production processes such as micro molding for decades.

Today, however, micro AM processes like the Fabrica 2.0 from Nano Dimension that we use at Accumold can now additively build parts and components only previously possible through the use of micro molding, and can do so in a way that allows manufacturers to completely re-imagine the way that precision micro parts and components are made, and which changes the basic economics of manufacturing.

The Fabrica 2.0 can attain 1.9 micron resolution in X and Y, and the technology builds “additively” in 1-5 micron layers. With this breakthrough, the path to the creation of innovative miniaturized parts at amazing speed and reduced cost is open for all industry sectors.

WHAT DOES THIS MEAN FOR MANUFACTURERS

The Fabrica 2.0 micro AM platform promotes innovation, and stimulates cost and time-to-market reductions. But in general terms, success through the use of the Fabrica 2.0 is measured in microns and hours. Micron-level detail can be achieved without the need to fabricate tools, and this means that you can have intricate and geometrically complex prototypes in a matter of hours.

There is a limit to the ability to create complicated parts using traditional micro tooling. With increased complexity comes increased cost, but not when using the Fabrica 2.0 micro AM technology. The absence of the requirement for a physical tool lifts the lid for design engineers to think out of the box and attain design goals previously unimaginable. This design freedom coupled with the inherent manufacturing agility that is a core characteristic of AM require a root and branch re-assessment of all aspects of the product development process, a disruption that is a spur to the stimulation of future product successes and enhanced market-share and profitability.

Through the use of the Fabrica 2.0, you can also optimize workflow, the technology producing less scrap and fewer tools than conventional manufacturing processes. It also promotes the reduction of iterative process, assembly, and inventory. This means that significant operational cost benefits are now attainable at the micro manufacturing level.

But there’s more! Through a combination of design optimisation and improvements in materials, we are able to additively manufacture Direct Rapid Soft Tooling (DRST) which we can use to injection mold real parts. This unlocks new business possibilities for mold makers and manufacturers who up until this point have been restricted to the use of long lead time and expensive traditionally manufactured mold tools for the achievement of any volume of molding, from prototype runs all the way through to mass manufacture. The business case for a process chain that includes DRST, with dramatically shorter lead times at reduced cost is obviously compelling.

REAL TIME CASE STUDIES

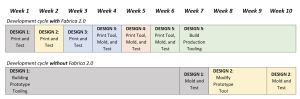

At Accumold, we use micro AM as a tool to reduce the time from initial design to market. When looking at a conventional prototyping scenario, prototype tooling needs to be fabricated at often considerable cost, and also taking upwards of 6 weeks, meaning that initial testing cannot take place until at least week 7 of a product development process. The time involved when using conventional tooling is only exacerbated if (as is often the case) design changes are required, and tooling needs to be modified.

When using micro AM, by week 7 a design can have been refined numerous times as the process requires no traditional tooling, just DRST. This means that time and focus in this early stage of product development can be spent on design optimisation, and so micro AM not only saves time and cost in product development, but it also stimulates innovation.

Table 1. A representation of how the use of micro AM in a product development cycle can significantly reduce time to market which in itself reduces product development costs and stimulates design optimization.

The theoretical case for the use of micro AM in precision plastics part and component development is seemingly therefore extremely compelling. However, Accumold now has significant experience in using the technology for customers, and so we are able to illustrate the way in which micro AM has benefitted OEMS in real time.

Due to confidentiality issues related to the case studies discussed below, we are unable to include pictures of the products discussed. Pictures used in this article are non-related part shots that show the precision and resolution that can be achieved using the Fabrica 2.0 technology.

Case Study 1 – Intraocular Implant. Our first example is a medical OEM customer making an intraocular implant that measured 1.6 x 2.9 x 0.7 mm. The customer was up against a looming FDA submission deadline. The part design included a small gap on one side of the part. While the rest of the part design was pretty much frozen, the customer needed to determine what size gap would be optimal for the part considering that in its final assembly it would need to be accurately handled and safely implanted inside the eye.

Due to the micro size of this part, using the Fabrica 2.0 we could print a lot of samples in the 50mm x 50mm x 100mm print envelope of the machine. We successfully printed multiple samples of six different designs for the customer to test. This took less than 24 hours to design, print, post process, package, and ship out to the customer, which was able to complete their testing in about two weeks. Their tests proved one of the designs superior to all others, and this was the design the company froze and submitted for FDA approval. Had we not been able to provide multiple part iterations for testing at one time the customer would have had to delay their FDA submission or choose a design without adequate test data. Once the customer is satisfied with their test performance Accumold can start to design and build the production tool so that we can qualify the tool and scale up to meet production volumes.

Case Study 2 – Implant Tip. Another one of our medical device customers needed to finalize an implant tip design measuring 1.5 x 3.0 x 2.5 mm before the design freeze date. The customer needed a frozen design so that they could kick off tooling and not push out their overall project timeline. Using the Fabrica 2.0 we were able to print 16 different tip designs for the customer to evaluate. Again, we could print a lot of parts in the Fabrica 2.0 print envelope, and our first print included 10 samples of each of the 16 design iterations. It took less than 24 hours to design, print, post process, package, and ship the parts to the customer, which completed its testing in a few weeks and came back with 6 different modified designs for another round of testing. Our second print was turned around in about one day so the customer could quickly resume testing.

Once all testing was completed, the customer shared with us their frozen design. With that, we kicked off our mold manufacturing process with a DFM session to ensure the molded thermoplastic part would meet the quality and functional requirements defined by the customer. With project work starting a couple months prior, we already had an established line of communication with the customer so we could quickly design the production tool and production process understanding all the criteria that needed to be met.

Case Study 3 – Valve Assembly. The last example comes from another medical customer that was trying to finalize the design of a valve assembly measuring 9.0 x 9.0 x 10.7 mm. This valve was comprised of a softer material overmolded on top of a harder machined part. The valve needed to maintain a seal while being rotated within the final assembly.

Our first round of samples was molded in DRST with the Versaflex material. Testing found that we had a few dimensions out so the insert CAD models were updated, and new inserts printed a day later. The second round of samples worked better but we found the Versaflex was too rigid when rotating it in the test assembly. We then used the same printed inserts to mold parts in Sarlink. The Sarlink parts performed better in the test assembly, but some leakage was observed. Sources of the leak were identified, the CAD models were modified, and another set of inserts were printed. This final set of inserts produced valves that could be easily rotated in the assembly and did not leak.

From start to finish we were able to test three different DRST mold designs and two materials in about two weeks. The customer was extremely pleased with the results and was excited by how much we learned in such a short period of time.

SUMMARY

All of the successful case studies discussed would not have happened without the Fabrica 2.0 micro AM technology being used as a central tool in the product development process. Fundamental to the success of the Fabrica 2.0 is that it brings the benefits of AM to micro manufacturers for the first time, including hitherto impossible part complexity (enhancing design and functionality), no tooling costs, minimal set up costs, the ability to mass customise and personalise products, and the ability to produce DRST. As a versatile technology appropriate for prototyping, small batches, and potentially even mass manufacturing, the technology is now stimulating innovation in the micro manufacturing sector, and is truly changing the economics of manufacturing.

Image Supplied: www.accu-mold.com