Leading architectural firm WATG has won First Prize in the Freedom Home Design Challenge which invited architects, designers, engineers and artists from around the world to design the world’s first freeform 3D printed house.

Commissioned by Branch Technology, the challenge required participants to design a 600-800 square-foot single-family home that would “rethink” traditional architectural aesthetics, ergonomics, construction, building systems, and structure from the ground up.

Each submission was required to offer conceptual solutions for all aspects of the house. For instance, the building envelope was to consider material applications, fenestration and structure, and the interiors were to include a kitchen, bath, living area and one bedroom.

Additionally, building systems were to satisfy mechanical, electrical, plumbing and lighting requirements while allowing for passive solar design strategies at the same time.

WATG’s Chicago-based team – consisting of Daniel Caven, Chris Hurst, Miguel Alvarez and Brent Watanabe – won the competition with their unique design called “Curve Appeal”.

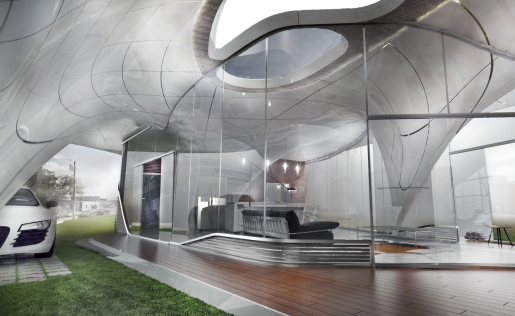

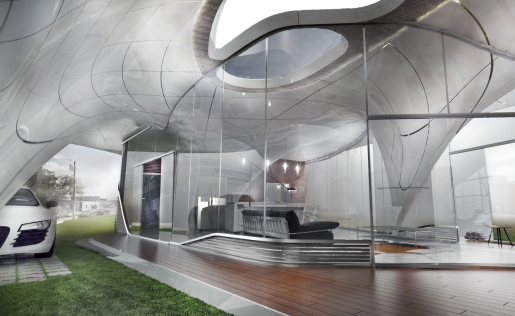

The design comprises of two main components: an interior core and exterior skin. The interior living spaces are designed to protect occupants from the elements via passive strategies while connecting them to the exterior spaces and nature itself.

The exterior skin, on the other hand, is derived from simple archways that ultimately “blend with the site” leaving an organic presence.

Branch Technology Founder, Platt Boyd said the proposal captured the potential for 3D printing to revolutionise design and construction.

“Curve Appeal is a very thoughtful approach to the design of our first house,” Mr Boyd said, adding that the house is set to begin planning phases in Chattanooga, Tennessee at Branch Technology’s lab and is expected to begin 3D printing in 2017.

“It responds well to the site conditions, magnifies the possibilities of cellular fabrication and pushes the envelope of what is possible while still utilising more economical methods for conventional building systems integration.”