Aerospace giant Boeing has selected metal additive manufacturing firm AML3D for a $140,000 key purchase agreement for the development of 3D printed structural test parts from aluminium material.

The agreement involves an intensive testing program comparative to the testing of structural components and in compliance with the requirements of AS9100D quality assurance for “fly” parts.

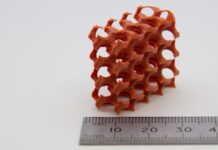

AML3D will use its proprietary Wire Additive Manufacturing (WAM) process to manufacture various aluminium test pieces and structure components, which will be sent for intense test evaluation in North America.

“This purchase contract is a major step in our journey and will provide the Company further opportunity to now validate and produce parts on time and to specification for a high-quality Tier 1 customer, which is further endorsement of the adoption of our proprietary WAM 3D printed solutions and core to our strategy for the company in the coming years,” said Andrew Sales, managing director for AML3D.